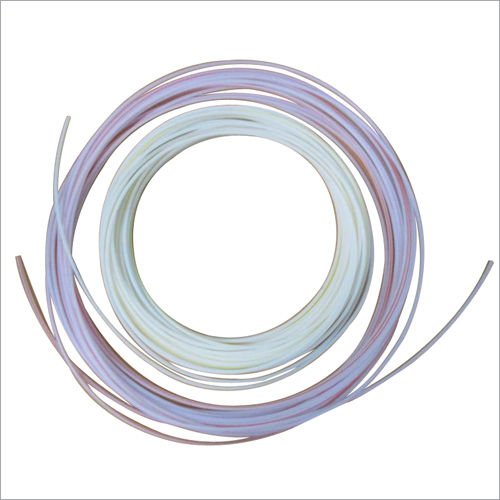

PTFE Pigmented Tubing

PTFE Pigmented Tubing Specification

- Type

- Pigmented PTFE Tubing

- Material

- PTFE with pigment

- Working Temperature

- -200C to +260C

- Density

- 2.17 Gram per cubic meter (g/m3)

- Corrosion Protection

- Excellent chemical and corrosion resistance

- Tensile Strength

- 21 - 28 MPa

- Thickness

- 0.2 mm - 3.0 mm

- Melting Point

- 327C

- Size

- Varies (inner diameter typically 1 mm - 25 mm)

- Width

- Custom as per requirement

- Length

- Available in standard or custom lengths

- Color Options

- Variety of colors as per application and requirements

- Flame Resistance

- Non-flammable, UL94 V-0

- Electrical Insulation

- Excellent, suitable for high voltage applications

- Elongation at Break

- 250 - 400%

- Hardness (Shore D)

- 50 - 55

- Odor

- Odorless and non-toxic

- Water Absorption

- <0.01%

- Surface Finish

- Smooth, non-stick finish

- Flexibility

- High flexibility even at low temperatures

- Standards Compliance

- Conforms to ASTM D3295 and other relevant standards

- Applications

- Medical equipment, chemical processing, electrical insulation, laboratory use

PTFE Pigmented Tubing Trade Information

- Minimum Order Quantity

- 50 Meters

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Supply Ability

- Meter

- Delivery Time

- as per order Months

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- CARTONS BOXES

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO : 9001 , 2015

About PTFE Pigmented Tubing

PTFE Pigmented Tubing

We offer PTFE Pigmented Tubing which is perfect to be used in medical applications. Known for its leak proof nature and fine finish, this tubing is made from pigmented polytetrafluoroethylene plastic material. Also, it is available in various lengths, finishes and orange color as per the clients requirements. Our provided pigmented tubing is highly popular in the market due to it's excellent resistant to hot vapor and physiologically neutral. Moreover, this PTFE Pigmented Tubing is ideal to transport liquid foodstuffs as well as pharmaceutical products and aggressive chemical liquids.

Key features:

- Suitable for repeated sterilization

- Rugged structure with smooth surface finish

- Uniform thickness

Tailored Color Options for Any Application

Choose from a wide selection of colors to match your application requirements or identification needs. Our pigmented PTFE tubing is engineered to maintain its vibrant color and exceptional properties even under harsh conditions, offering both aesthetic and functional benefits for your projects.

Exceptional Electrical and Chemical Performance

PTFE Pigmented Tubing is specifically designed to deliver superior electrical insulation and outstanding resistance to chemicals and corrosion. With a high working temperature range from -200C to +260C, it safeguards your systems even in extreme environments. Rely on it for secure performance in sensitive applications.

Customizable Specifications and Compliance

Available in a broad range of sizes and thicknesses (0.2 mm - 3.0 mm), our tubing can be manufactured to your custom width and length requirements. It fully complies with ASTM D3295 and relevant international standards, ensuring reliable quality for high-stakes industries such as medical, electrical, and laboratory fields.

FAQ's of PTFE Pigmented Tubing:

Q: How is PTFE Pigmented Tubing beneficial for electrical insulation?

A: PTFE Pigmented Tubing provides excellent electrical insulation, making it suitable for high voltage applications. Its non-flammable nature (UL94 V-0 rated) and ability to operate across a wide temperature range help safeguard electrical systems in demanding environments.Q: What color options are available for your PTFE tubing, and how does the coloring process affect performance?

A: We offer a variety of color options customized to your application needs. The pigmentation process does not compromise PTFE's core properties such as flexibility, chemical resistance, or electrical insulation, ensuring continued reliability with visual distinction.Q: When should I choose PTFE Pigmented Tubing over standard clear tubing?

A: Choose pigmented tubing when color coding, aesthetic requirements, or identification are important, or when you need the same non-stick, flexible, and durable characteristics as clear PTFE tubing-without sacrificing performance or compliance.Q: Where is PTFE Pigmented Tubing typically used?

A: It is commonly used in industries such as medical equipment manufacturing, chemical processing, electrical insulation, and laboratory research, thanks to its resistance to chemicals, corrosion, and extreme temperatures.Q: What is the process for customizing the size and length of the tubing?

A: Simply specify your required inner diameter (typically 1 mm to 25 mm), wall thickness (0.2 mm - 3.0 mm), and length (standard or custom). With these details, we manufacture tubing tailored to your needs while upholding stringent quality standards.Q: How flexible and durable is this tubing across temperature ranges?

A: Our PTFE pigmented tubing maintains high flexibility even at low temperatures, and offers impressive elongation at break (250 - 400%), making it durable and reliable in both cryogenic and high-temperature settings.Q: What are the main benefits of choosing this PTFE tubing from an exporter or manufacturer in India?

A: By sourcing from a reputable exporter or manufacturer in India, you gain access to globally compliant, customizable tubing, excellent support, and competitive pricing, ensuring high-quality solutions for industrial, medical, or scientific applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PTFE Tubing Category

PTFE Striped Tubing

Price Range 30.00 - 220.00 INR

Minimum Order Quantity : 50 Meters

Thickness : 0.1 mm to 2 mm

Type : Striped Tubing

Width : Customizable (as per requirements)

PTFE Markable Tubing

Price 250 INR

Minimum Order Quantity : 500 Meters

Thickness : 0.25 mm to 3 mm

Type : Markable Tubing

Width : As per requirement

PTFE Natural Tubing

Price Range 20.00 - 200.00 INR

Minimum Order Quantity : 50 Pieces

Thickness : Varies as per size

Type : Natural PTFE Tubing

Width : Customizable as per requirement

PTFE Extruded Tubing

Price Range 20.00 - 200.00 INR

Minimum Order Quantity : 50 Meters

Thickness : 0.5mm to 2mm

Type : Extruded Tubing

Width : Customizable

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS